Pyrolysis plant of plastic to fuel oil

Due to its low price, plastic products have become an indispensable consumer goods in our life. It is closely related to our life and brings great convenience and happiness to our life. But at the same time, he also brought great troubles to our living environment, causing serious pollution problems. In response to this problem, Doing Group's research and development team developed a pyrolysis plant of plastic to fuel oil.

The main process of pyrolysis plant of plastic to fuel oil are as follows:

1, First of all, the waste tires from the feed door into the host reactor, close the feed door, sealed. Heat the main furnace with fuel coal or wood in the heating chamber.

1, First of all, the waste tires from the feed door into the host reactor, close the feed door, sealed. Heat the main furnace with fuel coal or wood in the heating chamber.

2, When the temperature reaches 220 ℃, oil and gas precipitation, into the buffer chamber, residual oil (containing some slag) sink to the residue tank.

3, Light oil automatically enters the cooling system, condensed into oil.

4, Non-condensable gas, it will return to the reactor, as the heating reactor fuel.

The choice of our pyrolysis plant of plastic to fuel oil will give you an exact guarantee of your profit based on the unique advantages of our pyrolysis plant. These benefits are as follows:

1. Our pyrolysis reactor is manufactured according to pressure vessel production standards using a 16mm thick boiler special steel and arc head that withstands high pressures and temperatures.

1. Our pyrolysis reactor is manufactured according to pressure vessel production standards using a 16mm thick boiler special steel and arc head that withstands high pressures and temperatures.

2. High standard 3-step welding process, not easy to crack, long service life.

3. Pinion rotation device, small power, does not directly contact the reactor, heat transfer less easily deformed.

4. The three-stage cooling system uses tube condensers, also known as heat exchangers, which are currently the most commonly used and best performing condensers in the oil industry. Can ensure that the cracked oil and gas fully cooled, high oil production.

5. Our pyrolysis plant has the following safety devices: water separator, water seal, vacuum device. They prevent oil and gas backflows. Provide negative pressure, drainage oil and gas, so as to maximize the oil yield.

Nearly RMB ten thousand yuan of revenue can be gained from running one of our pyrolysis plant of plastic to fuel oil in a day, mainly from pyrolysis fuel and carbon black. They have the wide range use in dailylife:

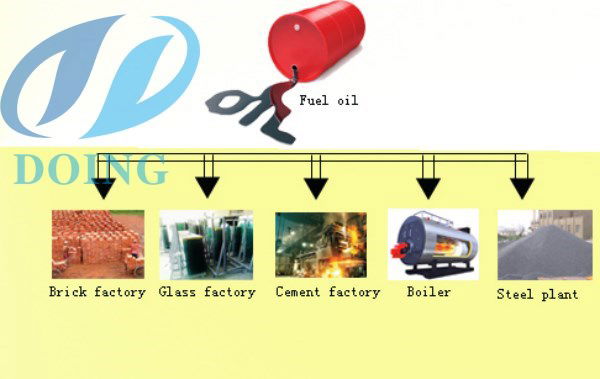

Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

Carbon black: mainly used for pressure ball burning, refining flour. Which refined flour and can be used for new tires, rubber soles, pigments of raw materials.

Are you interested in our pyrolysis plant of plastic to fuel oil, any pyrolysis plant problems, please feel free to contact me !!

Know more detail information ,click to chat us online!