Waste tyre to oil pyrolysis plant

As people's living standards improve, the car has become a must-have for people's travel. A wide variety of cars in the streets and lanes can be found everywhere. As small as bicycles to cars, people can bring different levels of travel convenience.

However, all things are two-sided, these cars bring convenience to people, but also pose a certain threat to our living environment. In particular, the waste tires on these cars and the waste tires that have been piling up in landfills have caused great harm to our living environment. Faced with this social problem, DoingGroup's engineering team developed a waste tyre to oil pyrolysis plant.

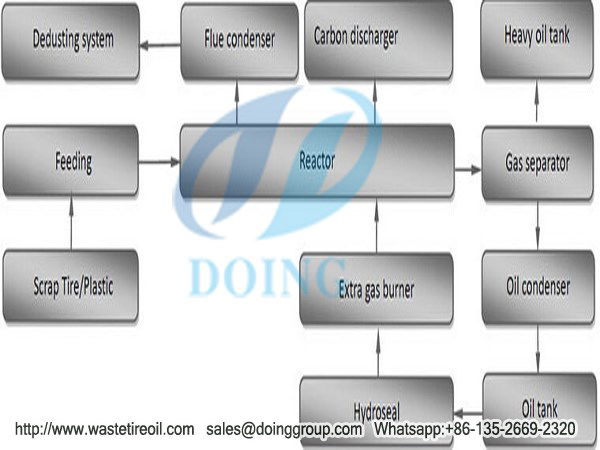

Waste tyre to oil pyrolysis plant, the main workflow:

1. The waste tire after automatic push device, into the reactor.2. The reactor is heated to a certain temperature, waste tires will be cracked into oil and gas.

1. The waste tire after automatic push device, into the reactor.2. The reactor is heated to a certain temperature, waste tires will be cracked into oil and gas.

3. After passing through the condensing unit, these hydrocarbons will be directly liquefied into fuel and flow into the oil tank. The other part will undergo filtration through the condensing system to maximize the liquefaction of oil and gas.

4. The resulting fuel after dust deodorization device, that is, we finally want the cracker oil.

5. Wait until the pyrolysis plant's reactor temperature of the reactor drops below 40 degrees, and then remove the inside of the carbon black, steel wire.

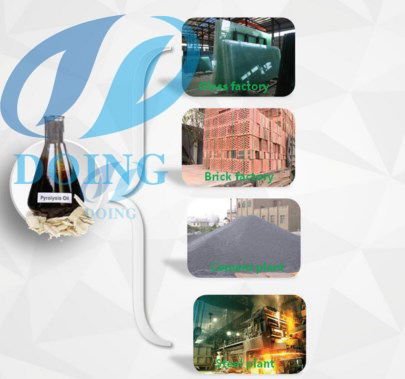

The operation of our waste tyre to oil pyrolysis plant will be able to get a profit of nearly ten thousand RMB everyday. These benefits mainly come from some low-molecular compounds such as fuel oil, carbon black, steel wire and combustible gas. These low-molecular-weight compounds have been cleaved from waste tires but have a wide range of uses in our life.

Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

Carbon black: mainly used for pressure ball burning, refining flour. Which refined flour for the new tires, rubber soles, pigments of raw materials.

Steel wire: mainly used for scrap recycling and re-casting.

Combustible gas: it will be recycled again by the pyrolysis plant and used again for heating the reactor.

So our waste tyre to oil pyrolysis plant and other home pyrolysis plant, what are the outstanding advantages? Details as follows:

1. Reactor steel using Q245R steel, 16mm after the boiler plate for steel. The advantage of this plate is able to withstand high temperature, high pressure.2. For the welding process we strive to be perfect, using a high standard 3-step welding process, this process is characterized by not easy to crack, long service life.

1. Reactor steel using Q245R steel, 16mm after the boiler plate for steel. The advantage of this plate is able to withstand high temperature, high pressure.2. For the welding process we strive to be perfect, using a high standard 3-step welding process, this process is characterized by not easy to crack, long service life.

3. Heating system design has insulation layer, to ensure that the temperature is not easy to lose, save heating energy.

We can meet your requests depanding on your budgets and needs, any questions of the waste tyre to oil pyrolysis plant please contact us!!

Know more detail information ,click to chat us online!